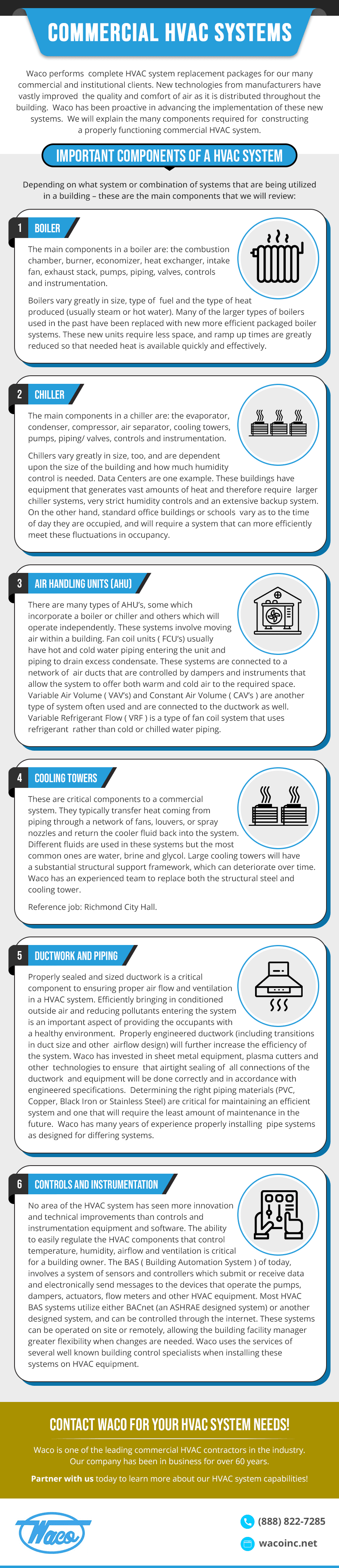

Commercial HVAC Systems

Waco performs complete HVAC system replacement packages for our many commercial and institutional clients. New technologies from manufacturers have vastly improved the quality and comfort of air as it is distributed throughout the building. Waco has been proactive in advancing the implementation of these new systems. We will explain the many components required for constructing a properly functioning commercial HVAC system.

Important Components of a HVAC System:

Depending on what system or combination of systems that are being utilized in a building – these are the main components that we will review:

*Boiler *Cooling Tower

*Chiller * Ductwork & Piping

* AHU * Controls & Instrumentation

Boiler

The main components in a boiler are: the combustion chamber, burner, economizer, heat exchanger, intake fan, exhaust stack, pumps, piping, valves, controls and instrumentation.

Boilers vary greatly in size, type of fuel and the type of heat produced (usually steam or hot water). Many of the larger types of boilers used in the past have been replaced with new more efficient packaged boiler systems. These new units require less space, and ramp up times are greatly reduced so that needed heat is available quickly and effectively.

Chiller

The main components in a chiller are: the evaporator, condenser, compressor, air separator, cooling towers, pumps, piping/ valves, controls and instrumentation.

Chillers vary greatly in size, too, and are dependent upon the size of the building and how much humidity control is needed. Data Centers are one example. These buildings have equipment that generates vast amounts of heat and therefore require larger chiller systems, very strict humidity controls and an extensive backup system. On the other hand, standard office buildings or schools vary as to the time of day they are occupied, and will require a system that can more efficiently meet these fluctuations in occupancy.

Air Handling Units (AHU)

There are many types of AHU’s, some which incorporate a boiler or chiller and others which will operate independently. These systems involve moving air within a building. Fan coil units ( FCU’s) usually have hot and cold water piping entering the unit and piping to drain excess condensate. These systems are connected to a network of air ducts that are controlled by dampers and instruments that allow the system to offer both warm and cold air to the required space. Variable Air Volume ( VAV’s) and Constant Air Volume ( CAV’s ) are another type of system often used and are connected to the ductwork as well. Variable Refrigerant Flow ( VRF ) is a type of fan coil system that uses refrigerant rather than cold or chilled water piping.

Cooling Towers

These are critical components to a commercial system. They typically transfer heat coming from piping through a network of fans, louvers, or spray nozzles and return the cooler fluid back into the system. Different fluids are used in these systems but the most common ones are water, brine and glycol. Large cooling towers will have a substantial structural support framework, which can deteriorate over time. Waco has an experienced team to replace both the structural steel and cooling tower.

Reference job: Richmond City Hall.

Ductwork and Piping

Properly sealed and sized ductwork is a critical component to ensuring proper air flow and ventilation in a HVAC system. Efficiently bringing in conditioned outside air and reducing pollutants entering the system is an important aspect of providing the occupants with a healthy environment. Properly engineered ductwork (including transitions in duct size and other airflow design) will further increase the efficiency of the system. Waco has invested in sheet metal equipment, plasma cutters and other technologies to ensure that airtight sealing of all connections of the ductwork and equipment will be done correctly and in accordance with engineered specifications. Determining the right piping materials (PVC, Copper, Black Iron or Stainless Steel) are critical for maintaining an efficient system and one that will require the least amount of maintenance in the future. Waco has many years of experience properly installing pipe systems as designed for differing systems.

Controls and Instrumentation

No area of the HVAC system has seen more innovation and technical improvements than controls and instrumentation equipment and software. The ability to easily regulate the HVAC components that control temperature, humidity, airflow and ventilation is critical for a building owner. The BAS ( Building Automation System ) of today, involves a system of sensors and controllers which submit or receive data and electronically send messages to the devices that operate the pumps, dampers, actuators, flow meters and other HVAC equipment. Most HVAC BAS systems utilize either BACnet (an ASHRAE designed system) or another designed system, and can be controlled through the internet. These systems can be operated on site or remotely, allowing the building facility manager greater flexibility when changes are needed. Waco uses the services of several well known building control specialists when installing these systems on HVAC equipment.

Contact Waco for Your HVAC System Needs!

Waco is one of the leading commercial HVAC contractors in the industry. Our company has been in business for over 60 years.

Partner with us today to learn more about our HVAC system capabilities!

Comments are closed