Industrial Insulation Contractors

Insulation contracting work in an industrial facility requires a completely different set of qualifications and safety awareness compared to a commercial or residential project. The piping, ductwork and equipment systems will be operating at higher pressures and greater temperature fluctuations. These systems will be larger and more complex and require skilled craftsmen to properly insulate them.

The insulation team at most industrial plants will have to work around a variety of hazardous chemicals, such as acids, caustic, hydrocarbons and steam. Quite often these facilities are in operation while the insulation work is being done. This will demand a higher level of safety, planning and hazard communication before any work can be performed.

Access to the area where the repairs or insulation work is to be done is often difficult, and may require specialty scaffolding or manlifts. The job must be planned in advance regarding fall protection, confined space, work permits , lock out -tag out and whatever other hazards that each particular area may require. Additionally, it is often better to prefabricate the insulation and jacketing in a shop or somewhere safely away from the work area. In this way, the amount of time spent in the hazardous environment can be limited and productivity is improved.

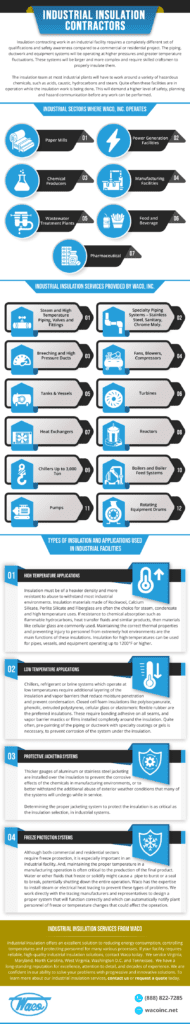

Industrial Sectors where Waco, Inc. operates

- Paper Mills

- Power Generation Facilities, (coal, oil, natural gas, nuclear, hybrid / renewable fuels, solar ,wind)

- Chemical Producers

- Manufacturing facilities

- Wastewater Treatment Plants

- Food and Beverage

- Pharmaceutical

Industrial Insulation Services provided by Waco, Inc.

- Steam and high temperature piping, valves and fittings

- Specialty piping systems – stainless steel, sanitary, Chrome Moly,

- Breeching and high pressure ducts

- Fans, blowers, compressors

- Tanks & Vessels

- Turbines

- Heat exchangers

- Reactors

- Chillers up to 3,000 ton

- Boilers and Boiler feed systems

- Pumps

- Rotating equipment drums

Types of Insulation and Applications Used in Industrial Facilities

High Temperature Applications:

Insulation must be of a heavier density and more resistant to abuse to withstand most industrial environments. Insulation materials made of Rockwool, Calcium Silicate, Perlite Silicate and Fiberglass are often the choice for steam, condensate and high temperature uses. If resistance to chemical absorption such as flammable hydrocarbons, heat transfer fluids and similar products, then materials like cellular glass are commonly used. Maintaining the correct thermal properties and preventing injury to personnel from extremely hot environments are the main functions of these insulations. Insulation for high temperatures can be used for pipes, vessels, and equipment operating up to 1200°F or higher.

Low Temperature Applications:

Chillers, refrigerant or brine systems which operate at low temperatures require additional layering of the insulation and vapor barriers that reduce moisture penetration and prevent condensation. Closed cell foam insulations like polyisocyanurate, phenolic, extruded polystyrene, cellular glass or elastomeric flexible rubber are the preferred insulations. These require bonding adhesive on all seams, and vapor barrier mastics or films installed completely around the insulation. Quite often, pre-painting of the piping or ductwork with specialty coatings or gels is necessary, to prevent corrosion of the system under the insulation.

Protective Jacketing Systems:

Thicker gauges of aluminum or stainless steel jacketing are installed over the insulation to prevent the corrosive effects of the chemicals in manufacturing environments, or to better withstand the additional abuse of exterior weather conditions that many of the systems will undergo while in service.

PVC jacketing or specialty barrier films that receive continuous wash downs in food and beverage and pharmaceutical environments are used to maintain cleanliness and meet industry guidelines.

Determining the proper jacketing system to protect the insulation is as critical as the insulation selection, in industrial systems.

Freeze Protection Systems:

Although both commercial and residential sectors require freeze protection, it is especially important in an industrial facility. And, maintaining the proper temperature in a manufacturing operation is often critical to the production of the final product. Water or other fluids that freeze or solidify might cause a pipe to burst or a seal to break, potentially shutting down the entire operation. Waco has the expertise to install steam or electrical heat tracing to prevent these types of problems. We work directly with the tracing manufacturers and representatives to design a proper system that will function correctly and which can automatically notify plant personnel of freeze or temperature changes that could affect the operation.

Experience

Since 1963, the public has trusted Waco Inc. to provide the highest-caliber specialized services across many sectors, including energy, chemical manufacturing, food and beverage, pulp and paper mills, and more.

A few of our featured insulation projects include:

- Freeze Protection at HRSD Water Plant

- Pipe Insulation at Hampton Roads Bridge Tunnel

- Kapstone Pipe Insulation Project

- Steam Piping Insulation at University of Virginia

Industrial Insulation Services from Waco

Industrial insulation offers an excellent solution to reducing energy consumption, controlling temperatures and protecting personnel for many various processes. If your facility requires reliable, high-quality industrial insulation solutions, contact Waco today. We service Virginia, Maryland, North Carolina, West Virginia, Washington D.C. and Tennessee. We have a long-standing reputation for excellence, attention to detail, and decades of experience. We are confident in our ability to solve your problems with progressive and innovative solutions. To learn more about our industrial insulation services, contact us or request a quote today.