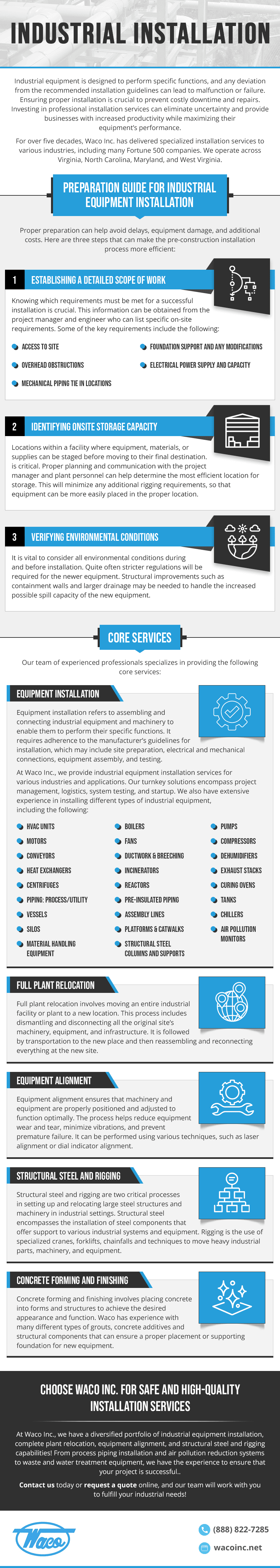

Industrial Installation

Industrial equipment is designed to perform specific functions, and any deviation from the recommended installation guidelines can lead to malfunction or failure. Ensuring proper installation is crucial to prevent costly downtime and repairs. Investing in professional installation services can eliminate uncertainty and provide businesses with increased productivity while maximizing their equipment’s performance.

For over five decades, Waco Inc. has delivered specialized installation services to various industries, including many Fortune 500 companies. We operate across Virginia, North Carolina, Maryland, and West Virginia.

Preparation Guide for Industrial Equipment Installation

Proper preparation can help avoid delays, equipment damage, and additional costs. Here are three steps that can make the pre-construction installation process more efficient:

1. Establishing a Detailed Scope of Work

Knowing which requirements must be met for a successful installation is crucial. This information can be obtained from the project manager and engineer who can list specific on-site requirements. Some of the key requirements include the following:

- Access to Site

- Foundation Support and any Modifications

- Overhead Obstructions

- Electrical Power Supply and Capacity

- Mechanical Piping Tie in Locations

2. Identifying Onsite Storage Capacity

Locations within a facility where equipment, materials, or supplies can be staged before moving to their final destination.is critical. Proper planning and communication with the project manager and plant personnel can help determine the most efficient location for storage. This will minimize any additional rigging requirements, so that equipment can be more easily placed in the proper location.

3. Verifying Environmental Conditions

It is vital to consider all environmental conditions during and before installation. Quite often stricter regulations will be required for the newer equipment. Structural improvements such as containment walls and larger drainage may be needed to handle the increased possible spill capacity of the new equipment.

Core Services

Our team of experienced professionals specializes in providing the following core services:

Equipment Installation

Equipment installation refers to assembling and connecting industrial equipment and machinery to enable them to perform their specific functions. It requires adherence to the manufacturer’s guidelines for installation, which may include site preparation, electrical and mechanical connections, equipment assembly, and testing.

At Waco Inc., we provide industrial equipment installation services for various industries and applications. Our turnkey solutions encompass project management, logistics, system testing, and startup. We also have extensive experience in installing different types of industrial equipment, including the following:

- HVAC units

- Boilers

- Pumps

- Motors

- Fans

- Compressors

- Conveyors

- Ductwork and breeching

- Dehumidifiers

- Heat exchangers

- Incinerators

- Exhaust stacks

- Centrifuges

- Reactors

- Curing ovens

- Piping: process/utility

- Pre-insulated piping

- Tanks

- Vessels

- Assembly lines

- Chillers

- Silos

- Platforms and catwalks

- Structural steel columns and supports

- Air pollution monitors

- Material handling equipment

Full Plant Relocation

Full plant relocation involves moving an entire industrial facility or plant to a new location. This process includes dismantling and disconnecting all the original site’s machinery, equipment, and infrastructure. It is followed by transportation to the new place and then reassembling and reconnecting everything at the new site.

Equipment Alignment

Equipment alignment ensures that machinery and equipment are properly positioned and adjusted to function optimally. The process helps reduce equipment wear and tear, minimize vibrations, and prevent premature failure. It can be performed using various techniques, such as laser alignment or dial indicator alignment.

Structural Steel and Rigging

Structural steel and rigging are two critical processes in setting up and relocating large steel structures and machinery in industrial settings. Structural steel encompasses the installation of steel components that offer support to various industrial systems and equipment. Rigging is the use of specialized cranes, forklifts, chainfalls and techniques to move heavy industrial parts, machinery, and equipment.

Concrete Forming and Finishing

Concrete forming and finishing involves placing concrete into forms and structures to achieve the desired appearance and function. Waco has experience with many different types of grouts, concrete additives and structural components that can ensure a proper placement or supporting foundation for new equipment.

Industrial Installation Projects

Waco Inc. has been a trusted provider of specialized services across various sectors, including energy, chemical manufacturing, food and beverage, and pulp and paper mills. Our commitment to delivering high-quality services has earned us the public’s trust over the years.

Here are some examples of our featured industrial installation projects:

- Longwood University Biomass Boiler Installation

- New Dust Collection System at Power Plant

- Process Equipment Piping System at Fiberglass Insulation Manufacturer

- Recycle Improvement at WestRock Paper Mill

- Coal To Gas Conversion of Power Plant – Richmond, VA

- JMU Burner Replacement / Boiler(s) Upgrade

Choose Waco Inc. for Safe and High-Quality Installation Services

At Waco Inc., we have a diversified portfolio of industrial equipment installation, complete plant relocation, equipment alignment, and structural steel and rigging capabilities! From process piping installation and air pollution reduction systems to waste and water treatment equipment, we have the experience to ensure that your project is successful..

Contact us today or request a quote online, and our team will work with you to fulfill your industrial needs!