Asphalt Plant Relocation and thermal improvements

PROJECT STATS

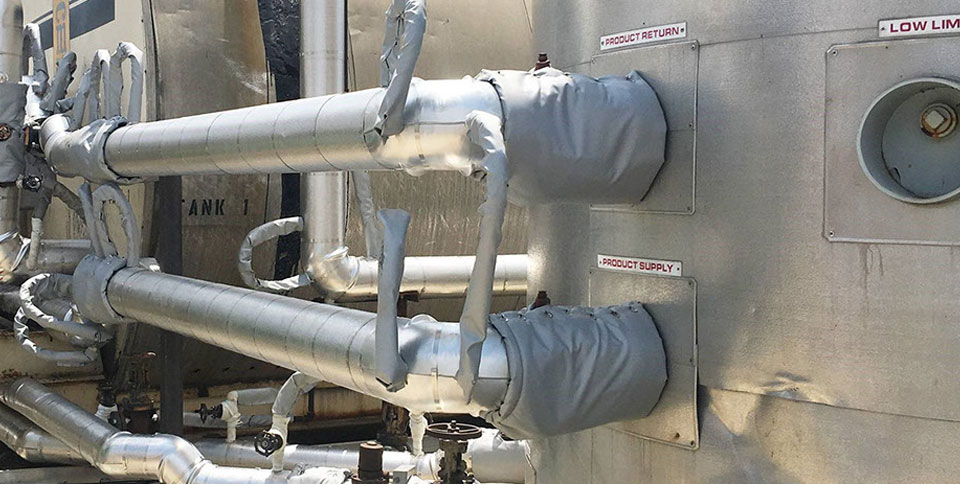

- Insulation of 1200 Lineal Feet of Piping

- Insulation of 62 jumper connections (Flexible Braided SS piping)

- Insulation of 2 Oil Pumps

- Insulation of 2 Manifolds

- Project completed in 6 weeks

About This Project

The use of asphalt as the preferred material for roadbeds and driveways has been steadily increasing. Several new facilities have recently been opened in the central Virginia area. There are many good reasons for using asphalt versus other materials:

- Most asphalt dries faster so installation times are reduced

- It is easier to prepare the surface when bonding to an existing roadbed

- Road drainage is improved due to asphalt’s unique ability to direct moisture away from the road surface.

- Reduced road noise.

- Recyclable material (RAP) – most asphalt that is removed can be sent back to the manufacturing plant and the material is reused or added back with the new asphalt mix. It is estimated that up to 70 million metric tons a year are recycled.

Asphalt plants that can store the asphalt product for several days in vertical silos are typically called drum plants. It is critical that these storage silos are properly insulated and can maintain the temperature so that the asphalt will continue to flow properly. The piping system at these facilities is also unique because the oil that is pumped along these lines must be kept at a temperature between 300 – 325 degrees F. The hot oil flows along piping in what are typically referred to as “ jumpers “. Proper insulation of the piping and manifolds is critical if the facility wants to reduce operating costs, control emissions, maintain a continuous flow of materials and increase safety (personnel protection).

What IT TOOK TO ACHIEVE THIS PROJECT.

Unique Project Challenges

This asphalt plant was relocated and placed near Petersburg, Virginia. Waco was contacted about insulation on both the oil storage tanks and the piping from the oil pumps throughout the process system. The storage tanks had some insulation remaining but many areas had damage due to being transported several hundred miles. The piping system would be new and installed on site. The piping was the most critical, in order to get the plant operational. This was not your typical pipe insulation project, because of the unique design of the jumpers and construction of the piping. It was critical that the protective metal jacketing be sealed properly to prevent damage to the insulation from weather, general maintenance and operations. Waco took extra care in spiral wrapping all the jumpers and then adding a protective silicone coated cloth to maintain the insulation integrity. Waco insulated over 1200 lineal feet of piping and the horizontal storage tanks will be insulated later in the year. The vertical silos came pre-insulated. Grady Sibold, one of Waco’s project managers, oversaw the successful completion of this project. Again, the Waco installation team came through ahead of schedule, while providing some unique methods for insulating this non-typical piping system.

Download a PDF of this Project