Boiler Replacement at fortune 500 company headquarters

PROJECT STATS

- Boilers: Additional 12MM BTU/HR

- 200 ft SS Flue (18" and 12" Diameter)

- Project Manager: Fletcher Braswell

- Superintendent: Todd Ackerman

- Completion: January 2019

About This Project

Waco has replaced quite a few boilers over the years. Often the actual boiler equipment is similar, but the uniqueness of the building and location of the mechanical room makes each project different and challenging.

This recently completed boiler replacement project was performed at a building listed on the U.S. National Register of Historical Places and the former headquarters of Reynolds Metals Company. The building was completed in 1958 and designed by Gordon Bunshaft, whose other accomplishments include the Hirshhorn Museum in Washington DC and Ford Motors Headquarters in Dearborn, Michigan. Unique to this four story building is the over 400,000 pounds of aluminum exterior cladding that, after 60 years, is still structurally sound and visually appealing. As with many buildings, the boilers and other major mechanical components are located in the basement with limited access for moving these large pieces of equipment. This is where an experienced team that knows how to coordinate with owners, engineers and other contractors becomes critical.

What IT TOOK TO ACHIEVE THIS PROJECT.

Unique Project Challenges

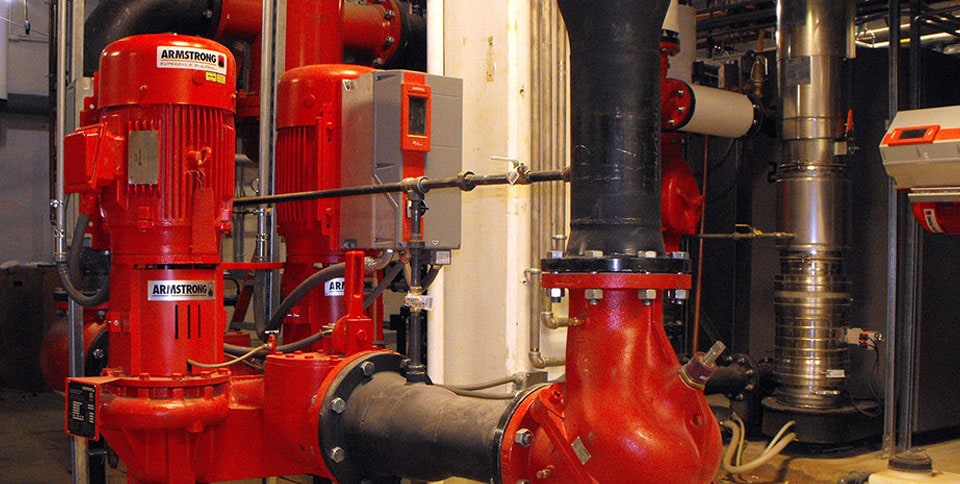

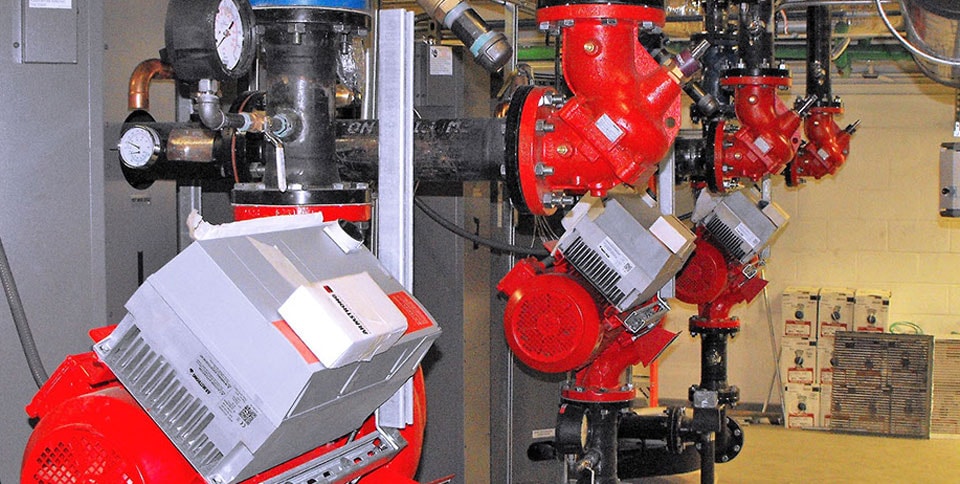

Waco first had to dismantle and remove in sections the two existing steam boilers. Our rigging crew planned out each step and safely disposed of the old system. The new system involved providing heat for the entire building as well as a new domestic water supply. The heating portion required the installation of three Lochinvar Crest® Hot Water Boilers each with a capacity of 4 million BTU’s/hour. To fuel these new boilers Waco had to upgrade the natural gas piping system. Many other components were installed to support the new design, including: three vertical HP pumps, two horizontal in-line pumps, a larger air separator, an expansion tank, 2 combustion air fans. Modifications to the 18 inch diameter exhaust flue were extensive and required installing two forty-foot vertical sections as well as several fitting connections and horizontal runs. Parts of the old flue had to be disassembled and removed to provide clear access for the new flue.

The domestic water supply upgrade required a new Hot Water Boiler rated at 800,000 BTU’s/hour, a new recirculation pump and a 650 gallon water storage tank. A 12 inch diameter exhaust flue had to be modified in order to support the new demands of this system. This exhaust flue extended 80 feet vertically and over 70 ft horizontally from the boiler room.

Waco’s team worked quickly and efficiently to remove and replace the old steam boiler system with new highly efficient hot-water boilers. There was not one day of disruption to the hot water and heating system of the building. Much credit goes to Todd Ackerman and his crew for outstanding performance on this project.