Recycle Improvement at Westrock Paper Mill

PROJECT STATS

- Replace conveyor system for screening recycled product

- Work with WestRock project engineers to develop and assemble a steel structure to support the new conveyor belt configuration

- Assist in evaluating an alternative water supply from within the plant to carry water to the new conveyor system

- Manage two 12-hour shifts including subcontractors for round-the-clock work schedules

- Project completion before the plant began full operations and within the allotted budget

About this PROJECT.

WestRock is one of North America’s leading producers of corrugated and consumer paper packaging products with plants located worldwide. One of their US-based plants in West Point, Virginia was slated for an upgrade of their recycle screening system.

This site has a full scale paper mill with 2 lines in continuous operation. In addition, the site operates a sophisticated system for recycling corrugated materials, including an automated method for screening out unwanted materials that come into the plant as part of bundled corrugated waste product.

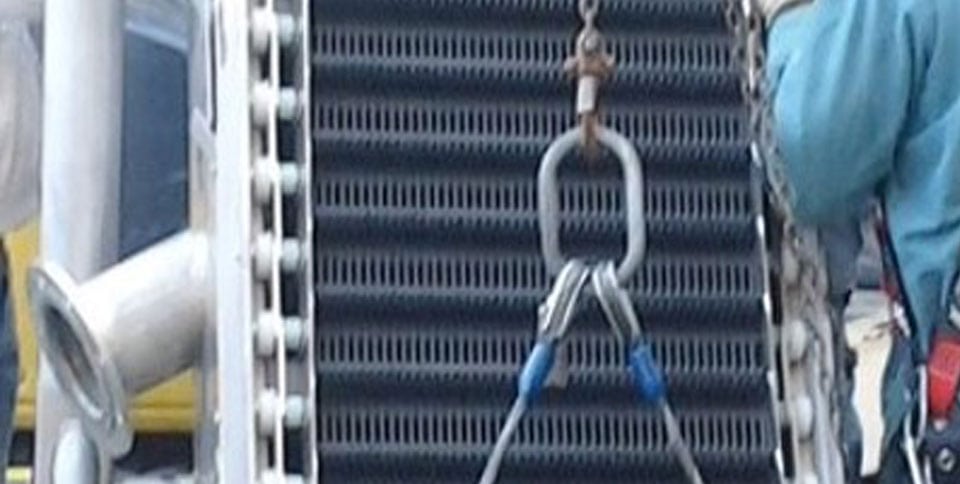

In an effort to improve product quality and gain the benefits of newer screening technologies, the plant decided to upgrade their conveyor-screening system. This system was comprised of a conveyor belt with an embedded screen to catch trash and residue as it runs through a water source located under the plant floor.

What IT TOOK TO ACHIEVE THIS PROJECT.

Unique Project Challenges

1.Extremely tight timeframe – the project had to be completed in 4 days during a scheduled plant wide shutdown. The mill could not re-open until the project was completed and tested. Nearly 2,000 labor hours were expended during the 4-day project.

2.Unanticipated impediments – it was determined after the project had started that the walls of the under-floor pit had to be cleaned out and re-worked. This required getting a backhoe into the pit, pumping out all fluids and completing a significant amount of concrete work. Waco secured additional manpower and was able to overcome these challenges, completing the project slightly ahead of schedule.

Contact Waco at 888-822-7285 for more information.

Why WACO was chosen

A reputation of successful projects and good economics

WestRock has a select approved contractor bid list of which Waco is part, and Waco brings trained supervision and workers to meet their specific requirements. This project was bid by several firms from the select bid-list. Waco had successfully completed several other projects at the plant and WestRock was confident in their ability to work quickly with high quality craftsmanship, and overcome any challenges that may arise.

Summary of Results

Gary Drake, Waco’s Project Manager, utilized a variety of trades including millwrights, welders, and pipe fitters along with subcontractors for concrete and structural steel work. There were no change orders, nor workplace injuries, and the project was completed within the allotted budget. The project’s success was further proof of Waco’s unique capabilities in paper mills, and adds to a growing list of many completed projects in this industry.