Waco PROJECTS

Nestle Purina Expands Cat Litter Facility

Nestlé Purina has recently completed a $182 million facility expansion with the help of Waco, Inc. The Nestlé “LDEL Project” produces clumping-type cat litter from locally mined Bentonite clay substrate found in King William County, Virginia. Bentonite clay-based cat litter accounts for almost 82% of the North American market share, and this new facility will be producing a greater share of that demand. The low-dust, enhanced-clumping capability and its ability to be scented have made it a preferred product for many cat owners.

New Huguenot Road Pump Station fulfills Chesterfield County’s increased Water Demands

The residents of Chesterfield County, Virginia, acquire the majority of their water needs from three main sources: The James River, Lake Chesdin and the Swift Creek Reservoir. Regional cooperation between the City of Richmond and Chesterfield County is critical due to the fact that a large percentage of the water (almost 24%) comes from the James River, through land located in the city. The Huguenot Road Pump Station is a good example of how this cooperation works for the good of the entire community. In this case, the actual pump station is located in Richmond, yet all the water will be going to Chesterfield County residents and businesses.

Overseas Corporations Find Waco is the Right Partner for USA Projects

Waco has had the privilege of working with several corporations that are based overseas and were expanding operations in the United States.

Waco’s wide range of services and our ability to coordinate with owners, engineers, project managers and field technicians provide a level of confidence that can be appealing to a foreign manufacturer evaluating prospective construction companies. Our certification programs for welding B31, ASME and R- Stamp all demonstrate that we are committed to quality assurance. We are comfortable with converting to metric units for lengths of measure, units and weights.

Freeze Protection Water Plant

Waco recently completed an insulation project at HRSD’s Williamsburg Treatment facility Odor Station A. This station has several pipe sizes from 3” to 16” diameter located outside that needed to be electrically heat traced and insulated to prevent the water and vapors inside from freezing. Waco coordinated with the electrical contractor who was installing the heat tracing. We determined that the most appropriate insulation system would incorporate using a one (1) inch thick closed cell Armaflex foam rubber insulation and an outdoor rated PVC jacket for weather protection. The project started at the end of October and needed to be finished by the end of November, before freezing temperatures set in.

Model Tobacco Renovation

Conversion of older warehouses or manufacturing buildings into residential apartments or condos has become very trendy these days, and nowhere more so than in Richmond, Virginia. Buildings of this type are structurally sound with solid foundations and are perfect for repurposing.

The Model Tobacco building was being converted into 203 apartment units of up to 3 bedrooms. There would be a 4,000-square-foot community section on the rooftop. The former power plant would be transformed into a recreational center with a pool, basketball court, gym, climbing wall and other recreational facilities.

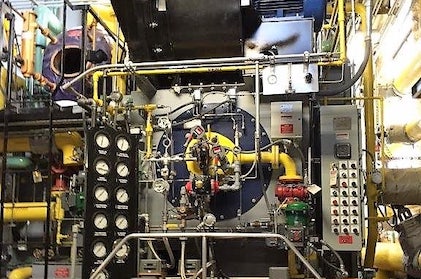

Conversion from Coal to Natural Gas at Cogeneration Facility

Conversions of older coal fired boilers to natural gas have been ongoing for over a decade. It makes more sense to convert an existing facility instead of building a new one since converting the existing boilers are 15-30% of the cost of installing new natural gas boilers. Waco recently completed a project with SourceOne (a Veolia Energy Company), to convert a cogeneration facility from coal to natural gas at the Veolia Spruance Plant. Rather than spending millions to dismantle and remove all the equipment that supported the use of coal, the conveyors, bag-houses and lime silos remained in place and are now inoperative. Waco worked with SourceOne engineers to develop ways to work around these structures and install the new gas piping, steam piping, burners, economizers, fans, pumps, ducts and breeching.

Waco Rebuilds Creighton Road Vent Station

Vent stations are an important part of all municipal and county sewer and waste water treatment systems. Many of these vent stations are located in populated areas, where odor control is of the upmost importance. Henrico County’s Creighton Road facility had reached a point where it would require the complete replacement of the piping, bio-filter system and building. Odor control is required at both the force main discharge and the head space in the wet well. The odor control method for this system is a bio-filter scrubber system. Large fans draw foul air from the wet well to the scrubber. Automatic controls meter any additional chemicals needed into the system. The hydrogen sulfide concentration in the air passes through the bio-filters until it is reduced to permissible limits before exiting the new stack.

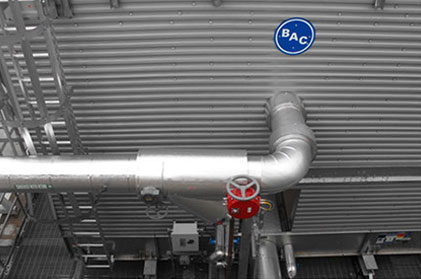

Rooftop Cooling towers replaced

Waco, Inc. replaces numerous cooling towers each year. The vast majority are basic projects that require moderate oversight and teamwork. When the project involves two cooling towers on top of a 19 story active downtown building – the coordination and expertise level increases substantially. Richmond City Hall is home to administrative and service offices of the City of Richmond, Virginia. It has over 78,000 sf of building space. The air conditioning system has two evaporative cooling towers. Each cooling tower sits upon a massive structural steel framework. Over the past twenty years, the cooling towers and steel framework had deteriorated so badly they needed to be replaced.

Boiler Replacement at Fortune 500 Company Headquarters

Waco has replaced quite a few boilers over the years. Often the actual boiler equipment is similar, but the uniqueness of the building and location of the mechanical room makes each project different and challenging. This recently completed boiler replacement project was performed at a building listed on the U.S. National Register of Historical Places and the former headquarters of Reynolds Metals Company. The building was completed in 1958 and designed by Gordon Bunshaft, whose other accomplishments include the Hirshhorn Museum in Washington DC and Ford Motors Headquarters in Dearborn, Michigan. Unique to this four story building is the over 400,000 pounds of aluminum exterior cladding that, after 60 years, is still structurally sound and visually appealing.

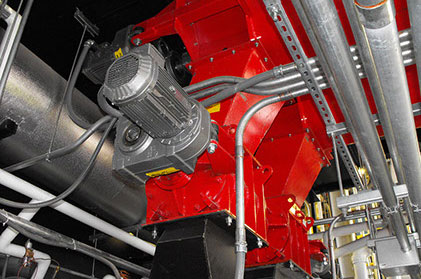

LONGWOOD UNIVERSITY BIO-MASS BOILER INSTALLATION

For over thirty years Longwood University has been utilizing bio-mass (sawdust & wood chips) as the main fuel source for their boilers that provide steam and hot water to most of the campus buildings. This is quite an achievement when many companies and facilities are just starting to tap into the benefits of using Bio-mass as a fuel component. Local sawmills and logging companies provide between 80-100 tons of sawdust per day. The economical and environmental efforts of the management team at Longwood have prevented these wood products from becoming just waste to be disposed of in landfills. This latest upgrade to the central utility plant will increase the capacity to over 80% of the university’s energy requirements.

Waco Goes to Any Depth to Complete the Job

The pump house at Lake Gaston contains 6 immense vertical pumps and motors for pumping the water through the 60 inch diameter pipeline. These pumps generate a large amount of heat and must be cooled by air conditioning. The existing cooling system consisted of a 40-ton chiller and an air handling unit. In an effort to reduce energy usage and operating costs, the City of Virginia Beach hired an engineering firm to design a more efficient system. The newly designed system would consist of an 80-ton TraneTM water source heat pump with two 40-ton geothermal heat exchangers.

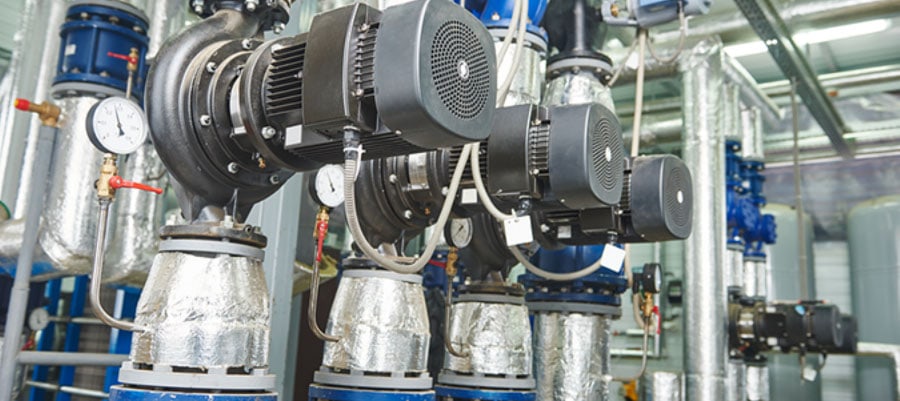

Ridge Road Pump Station Upgraded for Future Growth

The demands on the Ridge Road Pump Station in Henrico County, Virginia, could no longer be met with the current equipment. Essentially, a completely new pump station (except for the storage tanks) would need to be built. Waco won the contract and began construction in 2016. Much of the equipment had aged past it’s useful life. Many existing valves were so deteriorated that they would not completely close or open. Hot taps were utilized to bypass some valves to avoid service interruption. Once the new pumps and valves were tested and ready for service, the temporary bypass system could be disconnected and the old pump station could be demolished.

Fiberglass Insulation Manufacturer Teams with Waco

The demand for cleaner more energy efficient insulation products are clearly on the rise. The forecast for growth in the overall U.S. infrastructure will fuel this demand especially in the construction of new homes, apartments, mixed use developments, schools, hospitals and other structures. In response, a leading fiberglass insulation manufacturer chose to partner with Waco, Inc. for a major expansion of their manufacturing facility. This plant produces a light density building insulation, and the new line will utilize patented technology.

Pipe Insulation project at hampton roads bridge tunnel

Maintaining the bridge tunnel infrastructure is no easy task. VDOT relies on quality contractors to make necessary repairs which, if not done properly, can result in major traffic issues. A July 2009 water main break that flooded a portion of the tunnel resulted in a new plan of action, which required more frequent inspections of this critical piping. A recent test demonstrated that electrical heat tracing needed to be replaced. This heat tracing ran along the 8” diameter water main piping located underneath the bridge, between a man-made island and Hampton.

Insulated Fire Suppression in a refrigerated warehouse

In 2016, a cold storage facility located near Warsaw, North Carolina specified a wet pipe sprinkler system in a new building that would have operating temperatures at or below freezing. Waco was called upon to install electrical heat tracing on the pipes and then insulate them with two-inch thick fiberglass insulation. A .030” thick PVC jacket was then installed over the insulation. A red colored jacket was chosen so the sprinkler system could be easily differentiated from other piping.

Fuel Piping Upgrade at US Army Base

The Army’s training facility at Fort Lee in Virginia has experienced frequent problems with leaks in the fuel distribution system over the past few years. The current system of grooved coupling aluminum piping has certain advantages; It is a mobile system that can be quickly installed. This fuel depot at Fort Lee is a permanent installation and required a better piping design to eliminate leaks. The decision was made to install a welded steel piping system. Waco was awarded the contract to remove the original aluminium piping and replace it with new welded carbon steel piping.

Powell Courthouse Renovations

The Powell Courthouse, located in downtown Richmond, is one of only two major buildings surviving the fire that occurred during the evacuation of the Confederate army out of the city in 1865. It is the oldest courthouse building that the GSA manages. A new Federal Courthouse on Broad Street was completed in 2008. Once this new facility was completed, the GSA began exploring options for what to do with the additional space in the old courthouse. Many structural, mechanical and electrical changes would be required in order to upgrade this property and make it available for future tenants.

Maintenance Cost & Odor Reduction

at Waste Water Treatment Facility

Several factors can influence a clarifier’s performance at a waste water treatment facility. One of the toughest issues is the build-up of algae along the effluent launder channel. Excessive algae growth can limit the flow along the channel and reduce the clarifier’s effectiveness. It is also a chronic maintenance issue that requires frequent cleaning. Failure to perform these cleanings affects the overall productivity of the facility. Through a competitive bid process Waco was awarded the work to install Protecto-Lite fiberglass covers over two clarifiers.

Asphalt Plant Relocation

and thermal improvements

The use of asphalt as the preferred material for roadbeds and driveways has been steadily increasing. Several new facilities have recently been opened in the central Virginia area. This asphalt plant was relocated and placed near Petersburg, Virginia. Waco was contacted about insulation on both the oil storage tanks and the piping from the oil pumps throughout the process system. The storage tanks had some insulation remaining but many areas had damage due to being transported several hundred miles. The piping system would be new and installed on site.

Incinerator upgrades for waste water

FOR WASTE WATER TREATMENT FACILITY

Most waste treatment facilities have continued to expand as the volume of waste to them increases. There are many new technologies available today to help municipalities develop the best plan for effective treatment. At this particular facility, one of the methods of treatment is to incinerate a portion of the wastes. Incineration of wastes helps to reduce the overall volume of dry sludge and leaves a non volatile sterile residue.

Temporary Water Storage System for the town of crewe

During a planned inspection in the town of Crewe, it was determined that repairs and re-lining of their main water storage tank would be necessary. A temporary storage tank along with an operational pump station would be needed prior to taking the permanent water storage tank offline. The project was completed in time to begin the main water storage tank repairs. The temporary pump station and system will remain in place for 6 months and should be set to be remove from the site in October of 2016.

reactor replacement in hopewell

Ashland, Inc. is a Fortune 500 company that makes specially-formulated ingredients for standalone products, and as additives for other products. The applications for these ingredients include food and beverage, pharmaceutical, personal care, construction and several other industries. One of the company’s manufacturing plants is located in Hopewell, VA, just south of Richmond. This facility utilizes chemical reactors to manage the production and processing of several of their main products. Ashland needed to replace one of their reactors in the Natrosol production area.

Demolition of Tanks at an Old Paint Facility

It’s common to see old warehouses and large commercial buildings turned into apartment complexes or condominiums. The large, often open-layout spaces provide an incredible opportunity for developers to build the maximum number of units per square foot, without having to custom-build the exterior. The Manchester District located in southside Richmond has many buildings under renovation at this time.

Gas Piping Project For Henrico County

Methane is emitted during the handling of municipal wastewater through the decomposition of organic materials. Wastewater facilities are said to account for almost 7% of total global methane release. Most wastewater plants in the US, including the one in Henrico County, try to best utilize this renewable energy source. Waco worked with engineers from Hazen & Sawyer to determine and implement the best configuration for the piping system.

Steam Condensate System and Processing at Virginia Distillery

The Virginia Distillery is a multi-year project that will not only be the largest malt whisky distillery in the United States, but also one of the most energy efficient distilleries in the world. To craft high quality malt whisky, Virginia Distillery has imported two giant copper pot stills from the Highlands of Scotland in which to distill their product.

New Dust Collection System Developed for Power Plant

This West Virginia power station is a large coal fired facility producing enough electricity to power as much in one hour as 160 average homes use in one year. The station is located in the Allegheny Mountain range. The energy production process at the power station produces combustible dust, which must be collected and burned off.

Virginia Tech Boiler Superheat Upgrade Project

This project was comprised of adding a superheat surface within one of the boilers in order to increase power production from the turbine generator that produces electricity for the campus. Prior to completing this upgrade, two boilers were required to produce the needed energy for the turbine generator; and this project resulted in only one boiler operating to produce the same energy.

WestRock Screening Project

WestRock is one of North America’s leading producers of corrugated and consumer paper packaging products with plants located worldwide. One of their US-based plants in West Point, Virginia was slated for an upgrade of their recycle screening system. This site has a full scale paper mill with 2 lines in continuous operation. In addition, the site operates a sophisticated system for recycling corrugated materials, including an automated method for screening out unwanted materials that come into the plant as part of bundled corrugated waste product.

Kapstone Pipe Insulation Project

High pressure steam and heat are key components to producing the finest kraft paper and linerboard. The Kapstone plant located in Roanoke Rapids, North Carolina has been doing this for many years. The management decided that they needed to increase production at this facility. Installing additional steam piping would be required to meet the new demand. The new line would be over 500 lineal feet of 16 inch diameter steel piping carrying 800 lbs of pressure and operating at 850 degrees F.

Burner Replacement at University of Richmond

The University of Richmond’s power facility has 4 boilers, two of which were inactive at the time of this project. Due to increases in student population and greater requirements for steam and hot water, the University had to find ways to support the increased demand. The solution was to reactivate one of the previously coal fired boilers. The University is committed to using cleaner burning fuels and selected Waco to add a natural gas burner to the boiler.

HVAC replacement project at John Tyler Community College

The rooftop HVAC units at Moyar Hall had become old and unreliable, causing interruptions and high maintenance costs for the college. The decision was made to replace them and the work had to be completed during the Christmas season break. The total project involved replacing 3 packaged rooftop units and a small split-system located at another building on the campus.

Burner Replacement at James Madison University

JMU wanted to reduce energy usage on their heating and cooling expenses. One of the best ways to accomplish this was replacing the burner in one of the three boilers located within JMU’s power plant. Burner replacement in the other two boilers had been done previously, and the third replacement completed the boiler upgrade project.

Comprehensive HVAC Project at Longwood University

The HVAC system at Willett Hall, Longwood University’s athletic building, hadn’t been upgraded in 40 years. The system wasn’t performing well, and students and faculty were complaining. Additionally, Longwood sought to improve energy efficiency along with air quality throughout the building.

HVAC duct cleaning project for large data center

A new data center located in Boydton, VA, part of the Microsoft network of cloud computing centers, underwent major construction. The scope of the construction required a cleansing of the entire HVAC/air handling system before the center could become operational. Waco was brought in as a sub-contractor to complete the duct cleaning project.

Lead Paint Removal Project on Aircraft Carrier

The USS Roosevelt aircraft carrier, CVN-71, was undergoing a major renovation. After nearly 25 years of service, the USA’s nuclear aircraft carriers undergo a 3-year maintenance period to refuel their nuclear reactors, upgrade and modernize combat and communication systems, and overhaul the ship’s hull, mechanical and electrical systems. This is called a Refueling and Complex Overhaul (RCOH).

Extensive Mold Remediation Project

A vacant office building located in central VA was being re-conditioned in preparation for new tenants. The building had been vacant for a while, and due to leaks in the roof and humid summer temperatures, mold had formed on virtually all surfaces inside the building.

Industrial Cleaning Project at RockTenn Paper Mill in Lynchburg, VA

RockTenn is an American paper and packaging manufacturer based in Norcross, Georgia. It is one of North America’s leading producers of corrugated and consumer packaging and recycling solutions, with annualized net sales of approximately $10 billion

Rockbridge Regional Jail – HVAC, Security System and Roof Replacements

The Rockbridge, VA County Jail, located in Lexington, VA is a 30,000 sf building constructed in 1988. It has a population of nearly 100. The facility needed an upgrade of the security system to more modern technology, and sought to improve operating efficiencies by installing a fuel efficient HVAC system.

Asbestos Abatement Project for Hampton, VA Schools

A complete renovation project was undertaken by the Hampton, VA school district, which included new ceilings, lights, sound systems, flooring and seats at two auditoriums. In both locations the plaster lath ceilings contained asbestos materials, which had to be removed consistent with asbestos abatement guidelines. Waco was awarded the project at both locations.

Steam to Hot Oil Heating Conversion: A Multi-Faceted Mechanical Project

Purpose of the project was to convert a plastics production process supported by steam to one in which hot oil was used as the heating method. Hot oil was determined as a more effective and consistent method for heating raw materials, and would result in plant production improvements. (Photo pictured is for representative purposes only and is not the actual plant involved in this project, per agreement with our customer.)

Steam Piping Insulation Project at University of Virginia

Over the past several years the underground water and steam piping system at the University of Virginia (UVA) has been upgraded by section. The system runs through a 6 ft. x 6 ft. underground tunnel located throughout the campus. This particular project involved insulating a1,000 linear foot section of 12 inch steam piping.

Hazardous Waste Removal Project for the Capital Region Airport Commission in Richmond, VA

Buildings that previously housed the Virginia Air National Guard were located on the East side of the Richmond International airport. The buildings were planned for demolition in order for potential re-development of the land.

Demolition Project in Newport News

This project encompassed the demolition and debris removal of a large apartment complex. The complex was comprised of 138 townhouse apartment units in 19 separate buildings located on 10+ acres in Newport News. It was to be replaced by a new apartment complex with larger buildings to improve utilization of the real estate.

Thomas Dale High School- Developed New Cooling/Mechanical Building

Thomas Dale High School, a school of more than 2,500 students and faculty, had an existing mechanical and cooling room that was located in the middle of the school building. The project entailed creating a whole new mechanical and cooling building located on an out-parcel piece of land on the school’s property and adding two new chillers.

Washington Hall at Radford University-Interior Demolition & Asbestos Removal Project

Washington Hall at Radford University (RU) is an old dormitory that contained asbestos materials and lead paint. RU decided to completely gut the building for new electrical, mechanical and plumbing systems. Waco was awarded the contract to demolish the interior of the building, remove hazardous materials, complete LEED requirements for waste recycling, and prep the building for subsequent contractor groups coming in for re-development.